Services

Consultation & development

Do you need to implement a motion sequence for your entire application?

That is exactly what we can do for you!

With our broad-based R&D department, we will find the right product from our standard range – or develop and design products individually, tailored to your needs. With over 25 years of experience, we can look back on numerous successful projects in a wide range of high-quality segments such as the electronics and semiconductor industry, as well as medical engineering and automation technology. In doing so, we can offer you state-of-the-art technology for your solution.

Thanks to close project support, we are able to react quickly and flexibly to your changes throughout the various project phases, while at the same time keeping our eyes on the common goal. This allows you to optimally use your resources, while we take care of the motion task as a 360° partner.

Regardless of whether you require linear and rotary direct drives, or our extensive range of conventional drive technology, this approach gives you the decisive edge over your competitors.

You can simply get in touch with us directly or use our application sizing worksheet. Armed with your information, we can present you with the ideal solution.

Production & assembly

During the next stage of the project, the production and assembly activities begin. It is our task at this point to fulfil the individual needs of your application and to satisfy the high demands on dynamics, precision, economy and reliability.

You benefit from a high level of vertical integration thanks to our machinery on site in Vienna. In-house production of critical components and direct access to the supply chain enables us to react flexibly and with foresight to volatile conditions, while the highly trained team (with experience of over 4000 system deliveries per year) and established TQM ensures unbeatable quality in the long term.

For positioning applications in the sub-µm range, we can create an error compensation or correction matrix for you. And if you require it – we can also measure the system accuracies using a laser interferometer, plane glass and other Zerodur measuring equipment.

No matter whether you order a single axis or a multi-axis system from us, the same always applies: Only the highest quality is good enough for you.

In addition to a standardised factory commissioning, we can perform a complete 100% function check before delivery on request. We define individual test runs with you and carry them out in a standardised manner. Of course, each individual result is recorded and made available to you.

If you prefer to carry out the commissioning yourself, your individual parameter set can also be supplied with the desired accessories (cable, servo controller, motion controller, etc.). We are at your disposal for commissioning or on-site measurements. Comprehensive training and 24h telephone support completes our wide range of services.

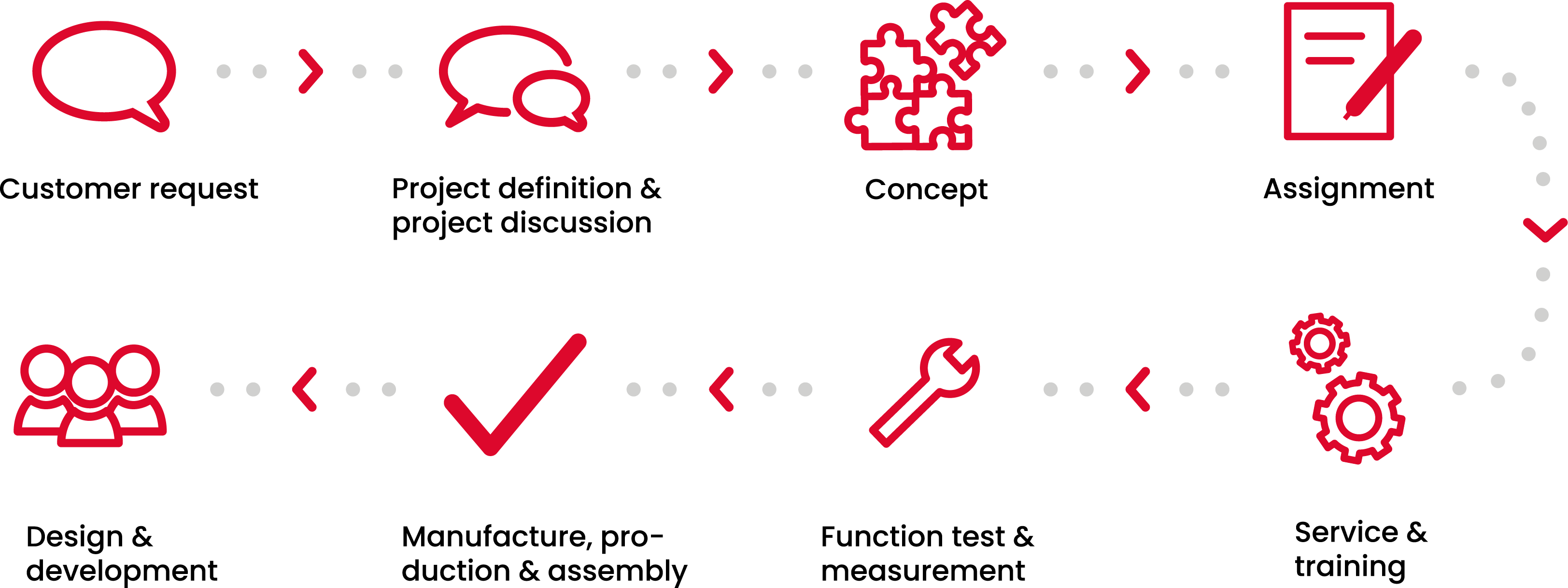

Process for your solution and our service: