Products

- Optimised smooth running bearing

- Unbeatable speed consistency

- Fastest response

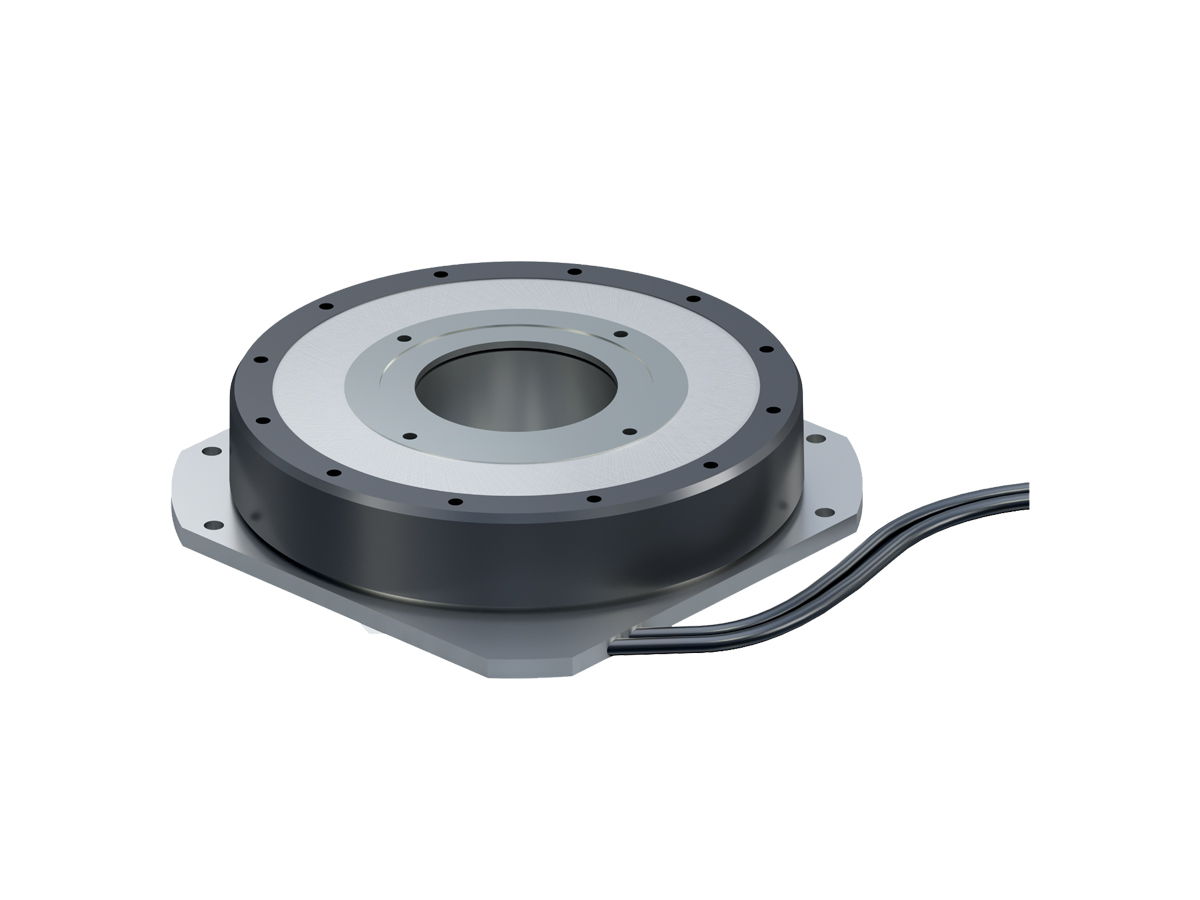

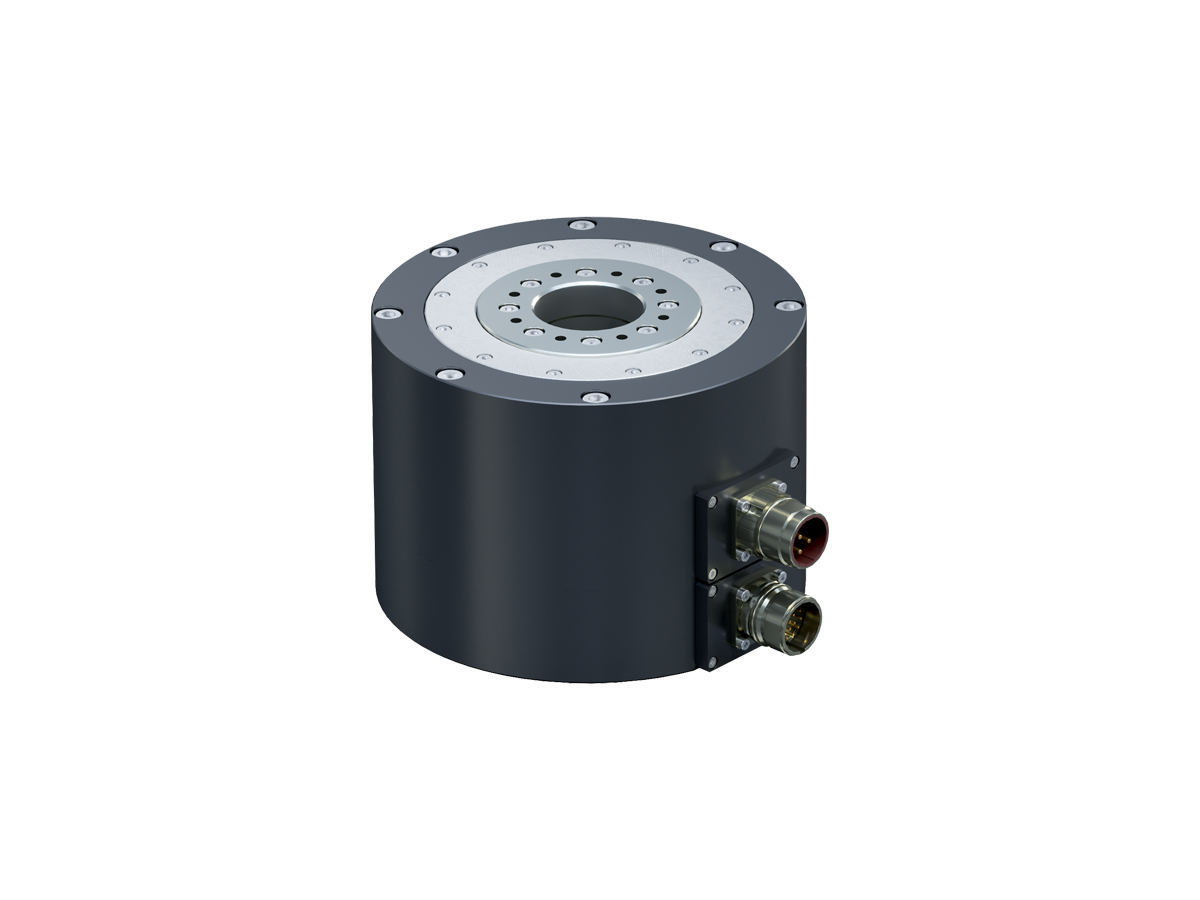

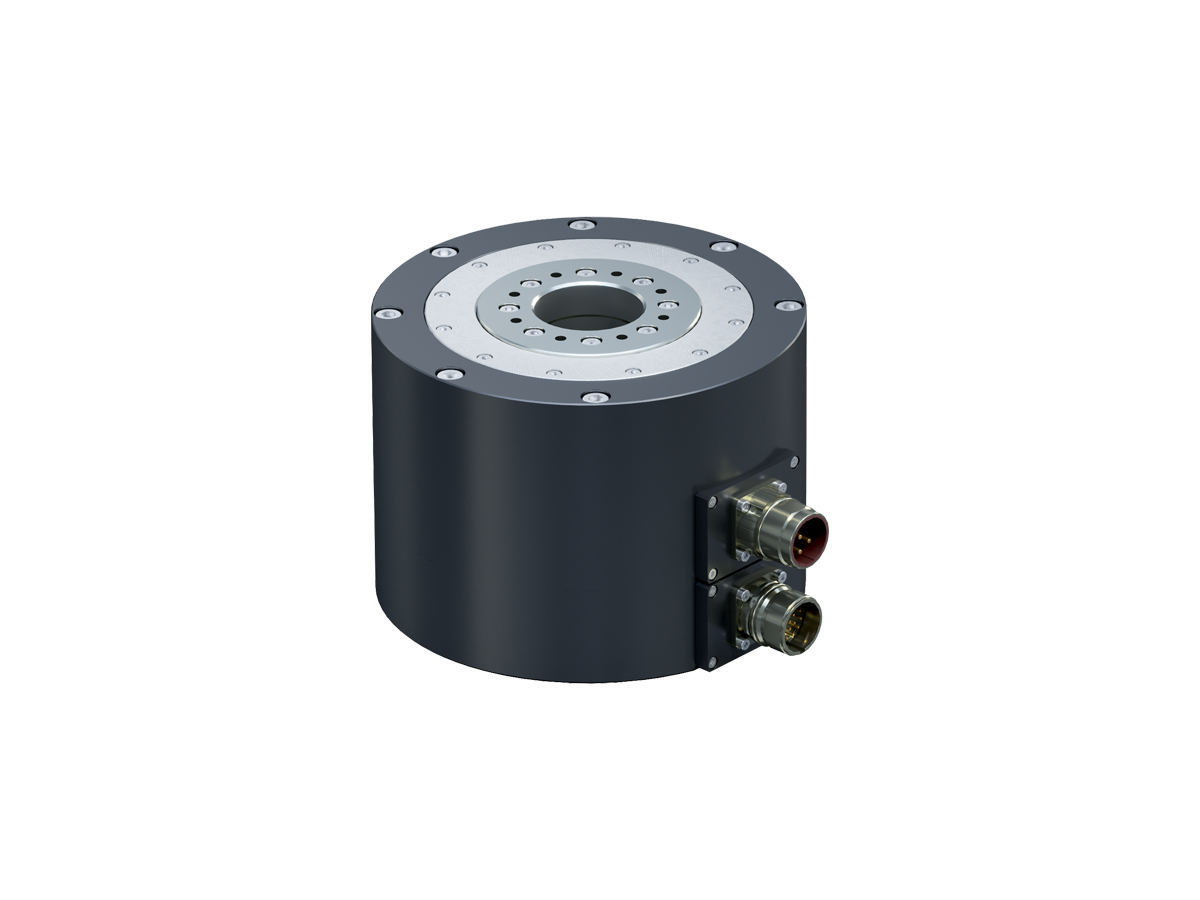

The KML high-speed rotary table series (RDD HS) was developed to position small to medium loads with high dynamics and large rotational dynamics. The rotary tables can be adapted to the respective customer electronics with a wide selection of different encoders, which means that applications can also be implemented according to Safety Integrity Level (SIL level).

The KML high-speed rotary table series can achieve high positioning accuracy at very high speeds due to its special design. Thanks to the special system composite of aluminium housing, the high-precision standpipe and the rigid bearing designed for dynamics, this can be ensured as standard.

Our standardised modular system makes it possible to configure and implement a system that optimally meets the customer’s requirements. The versions of the KML rotary table series are explained in greater detail in the type code and can be optionally selected according to your requirements.

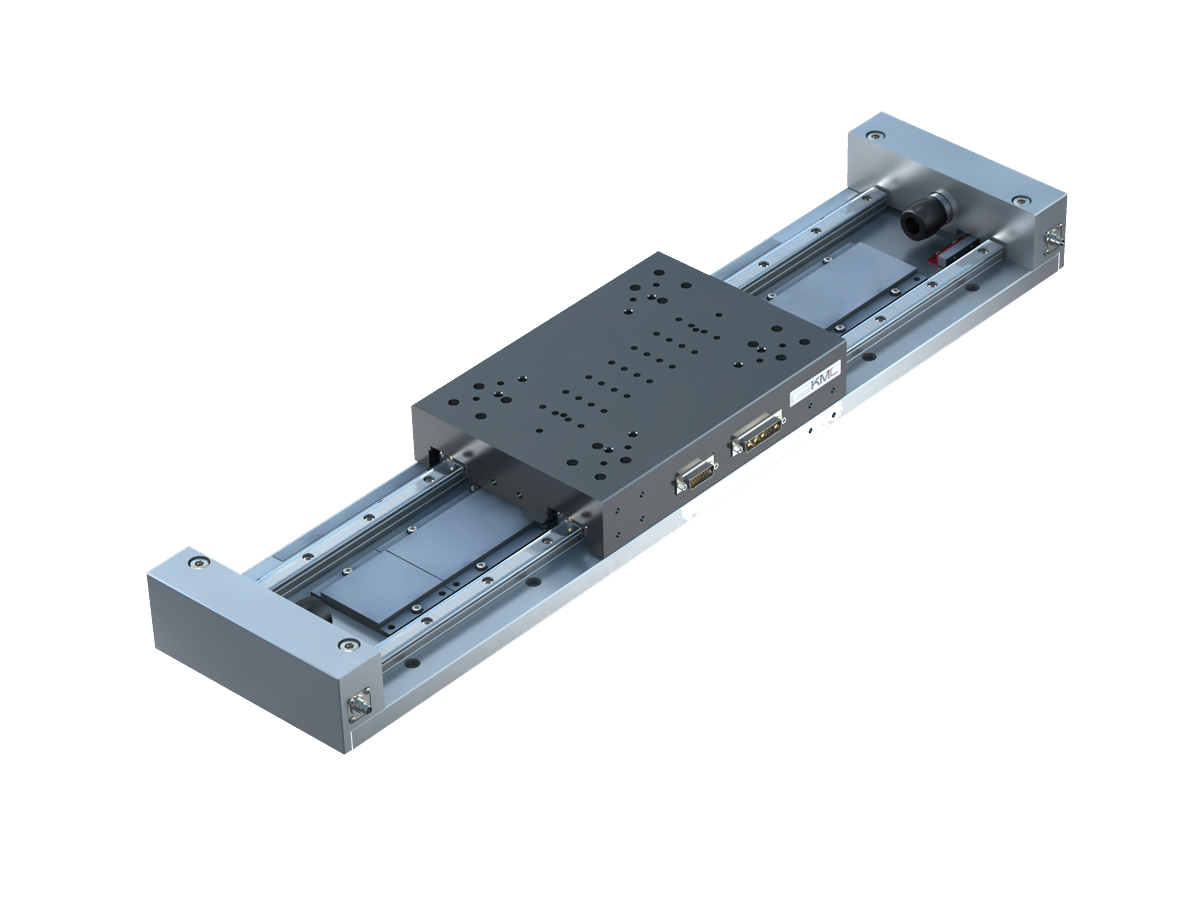

With our extensive range of accessories, any multi-axis solution can be configured. Combining the different series of our KML axes with standardised adapter parts means a high degree of flexibility is given in the configuration of multi-axis solutions, allowing the system to be optimally adapted to the individual requirements of the customer.

- Optics and mirror adjustment

- Rotary table applications

- Robot handling

- Laser processing

- X-ray

- AOI applications

- Test systems

- Printer systems

- Semiconductor manufacturing

| Type / size | |||||||

| Continuous torque | [Nm] | 2.60 – 21.9 | |||||

| Peak torque | [Nm] | 6.40 – 55.5 | |||||

| Max. speed | [rpm] | 724 – 10000 | |||||

| Max. continuous current | [A] | 3.93 – 16.90 | |||||

| Max. peak current | [A] | 7.73 – 48.80 | |||||

| Number of poles | [1] | 28 | |||||

| Repeat accuracy | [arcsec] | 35 |

Attention: Specified values are empirically determined and vary depending on the application.

The values are maximum values.