Products

- Compact design

- Uniform interface

- Unbeatable stiffness

- Concentricity accuracies in the µm range

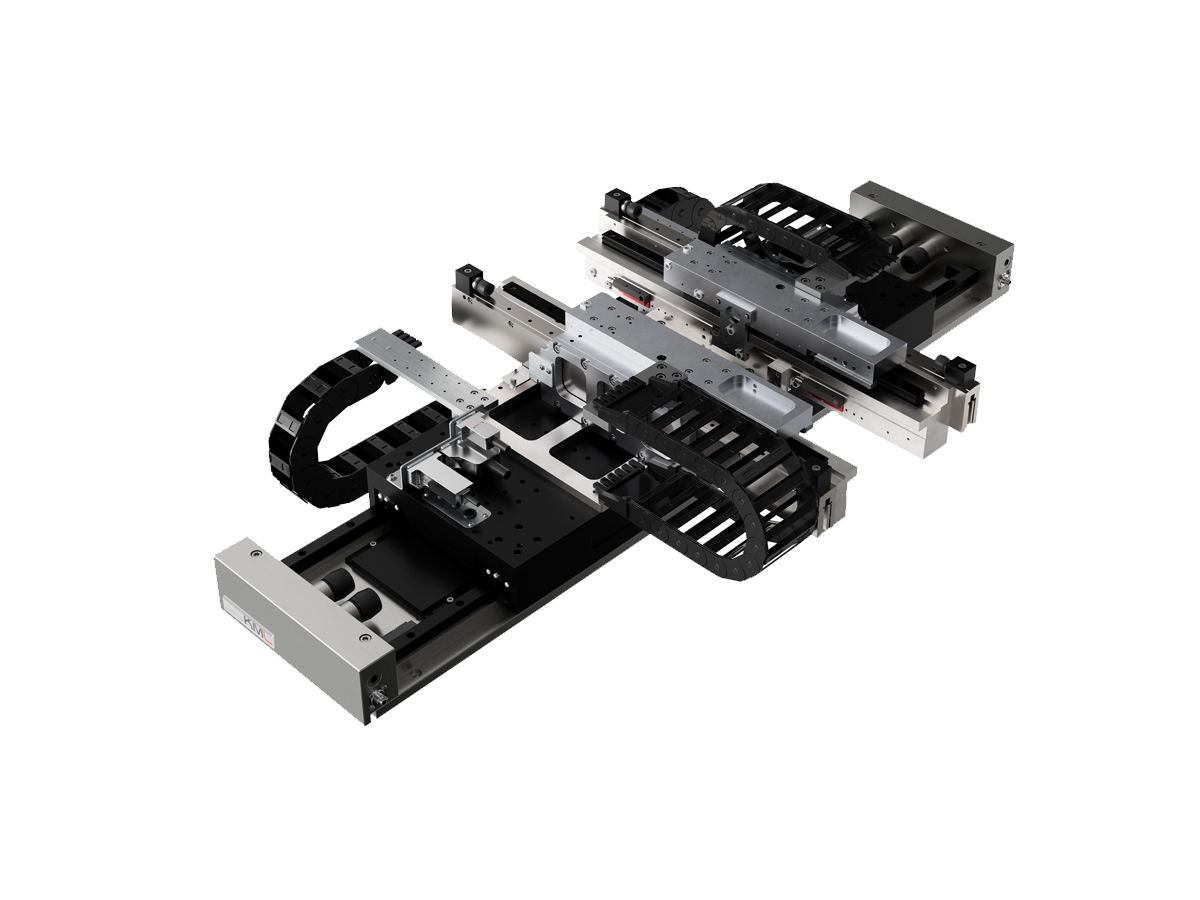

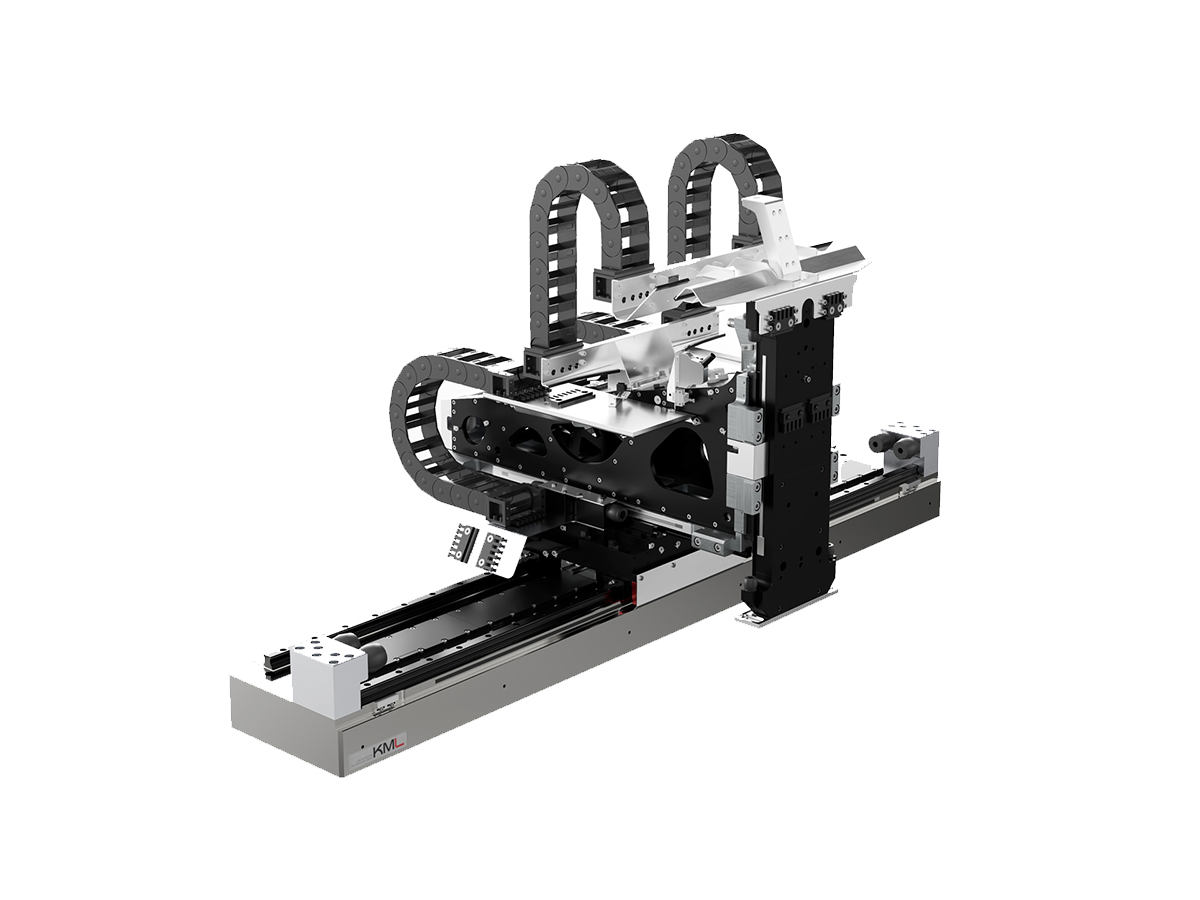

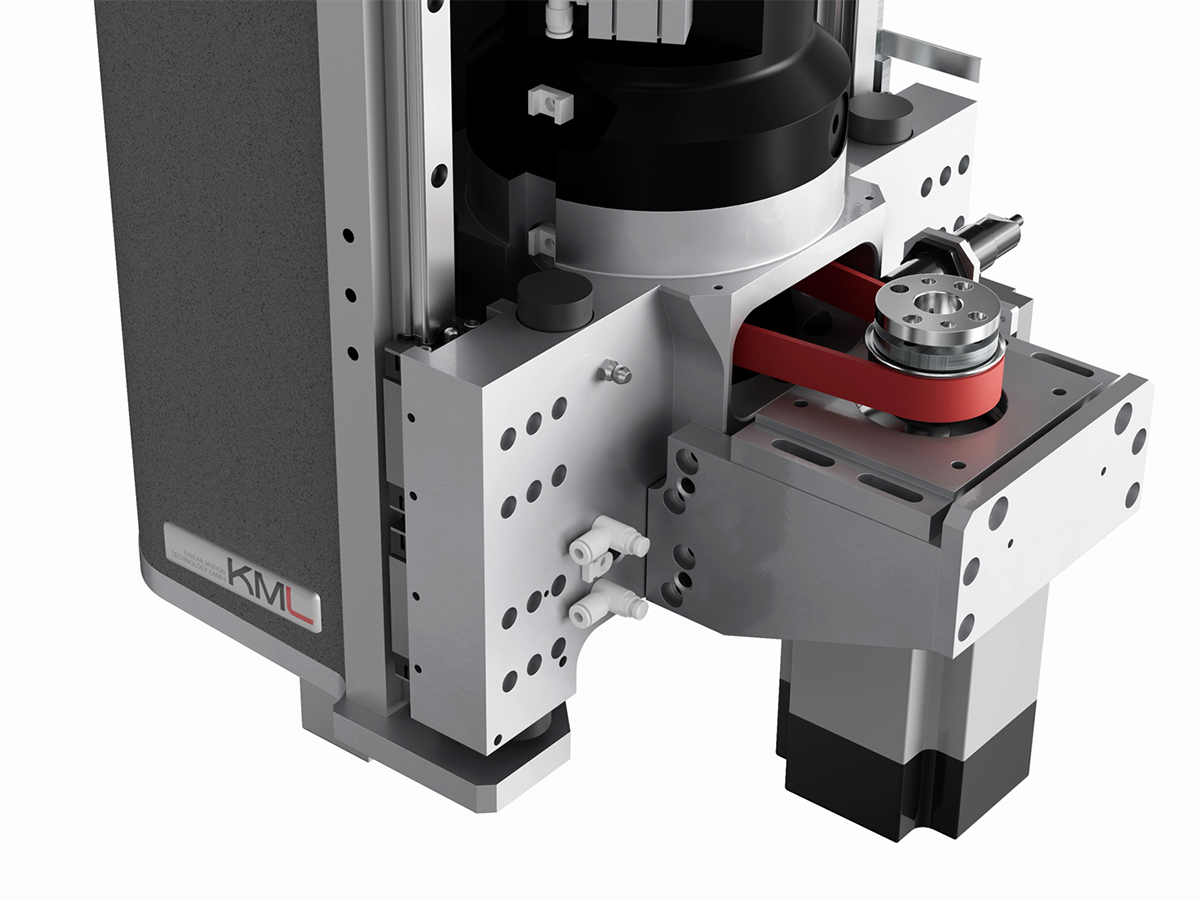

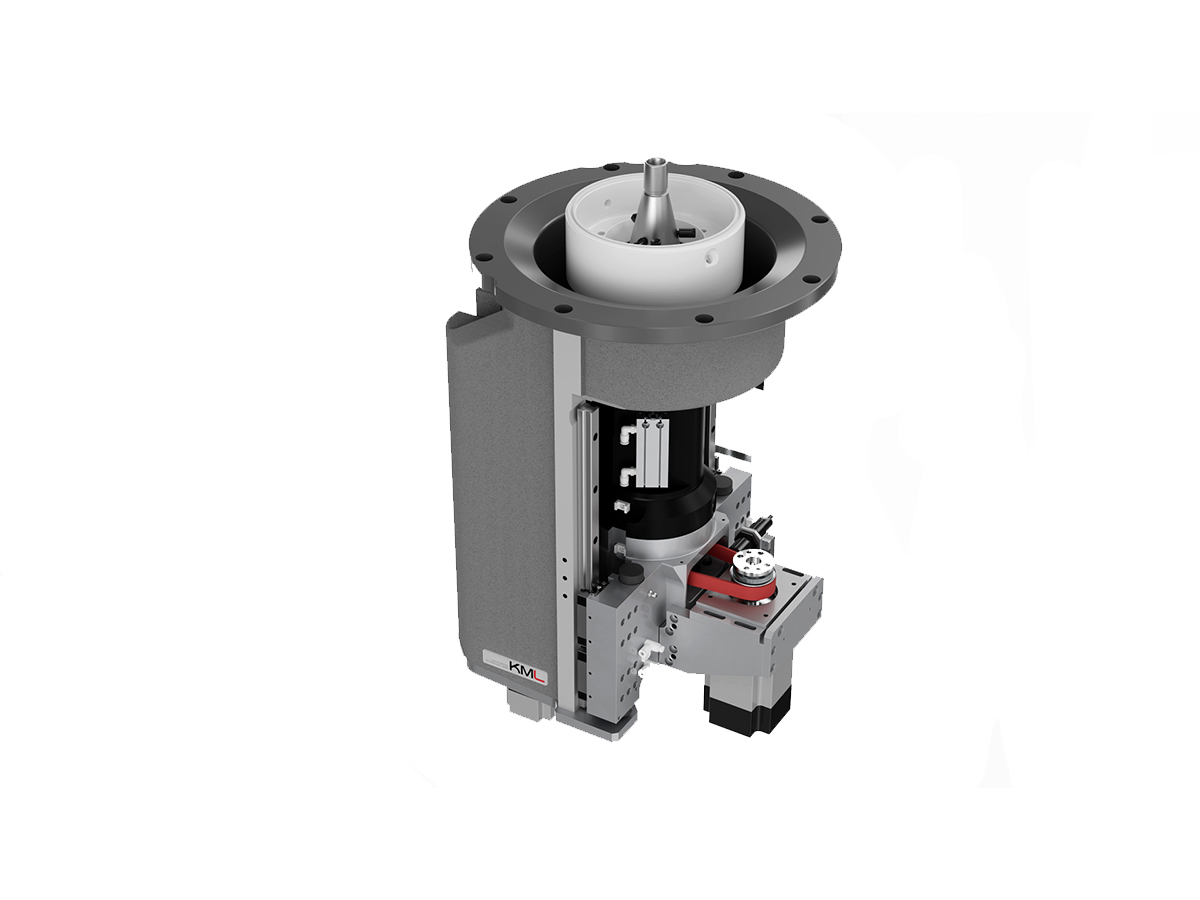

Different direct drive technologies are optimally suited to the precise and reliable realisation of manipulation tasks in an extremely small space. Linear swivel or rotary stroke applications require a combination of rotary and linear drive motion. The drive technologies available from KML are combined into an optimal motion solution using torque and linear motor technology.

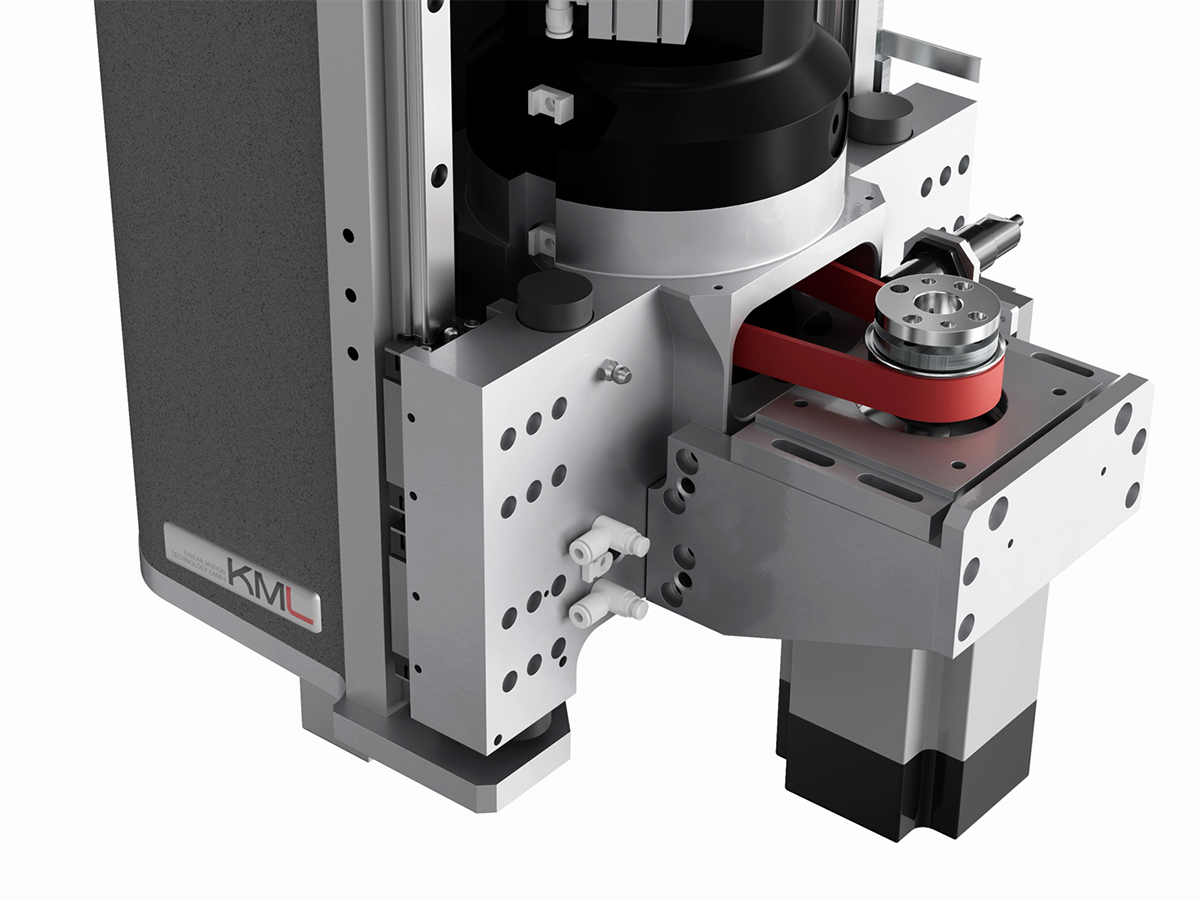

In addition to the usual customer requirements for wet-chemical machining processes, additional system requirements had to be taken into account. These included for example:

- Compact design

- Uniform interface (mech. /electr.)

- Concentricity accuracies of the rotary unit in the µm range

- Special materials against extremely aggressive media (acids, etc.)

- System suitability for the highest clean room classification

- Reliability and stability

- Almost 100% machine availability

- Easy to maintain

- Maximum rigidity of the entire system against highly dynamic interacting loads

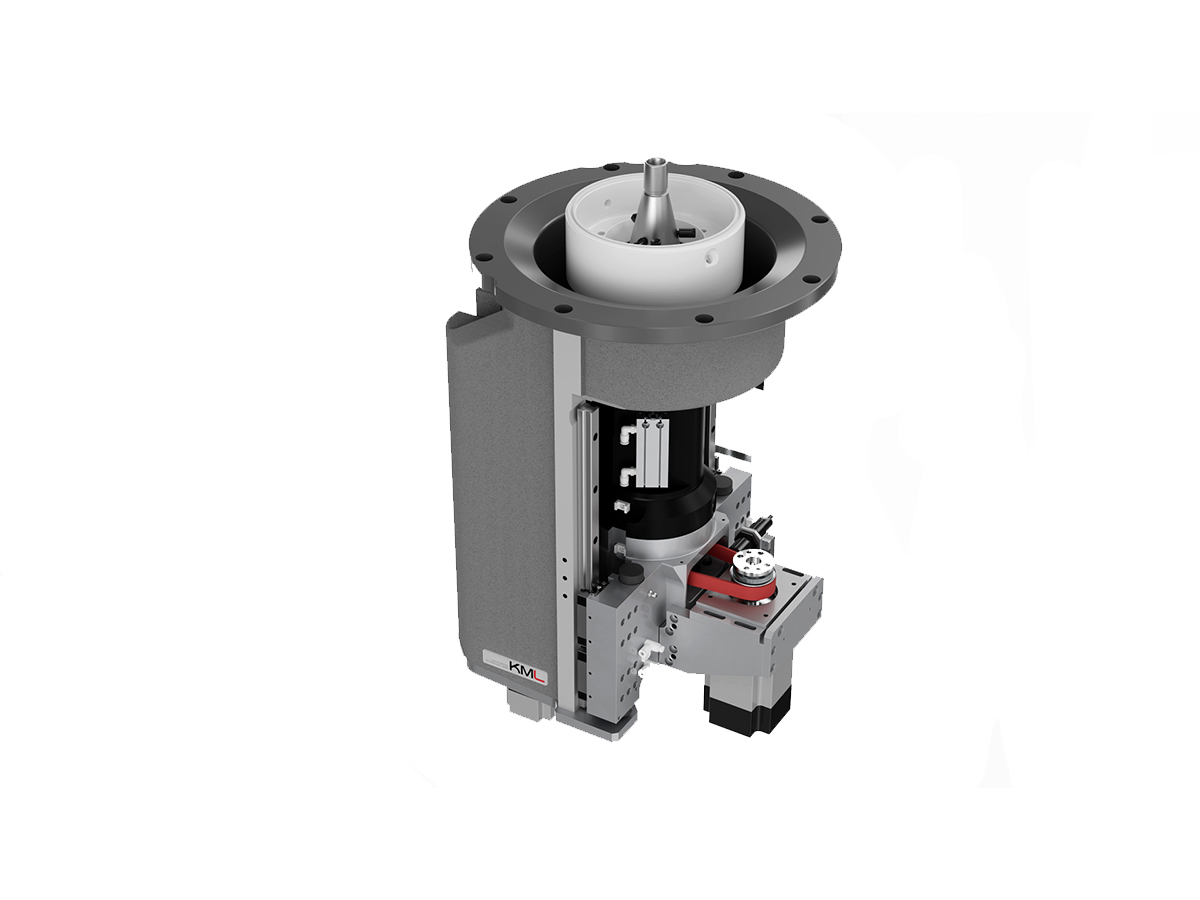

An integral and compact system solution was achieved with the help of the latest FEM methodology with the highest inherent rigidity:

- Cast base body made of compacted material

- Rotary axis with ball screw for vertical motion

- Special high-precision bearing hybrid pairing for rotary axis

- Hollow shaft direct drive and servo motor technology

- Pre-stressed stainless steel roller guides

- Special lubricant for all moving parts

- Special surface coating

- Vacuum chamber system for particle suppression

- 100% function control and qualified test process

- Semiconductors

- Spin processes

- Wet clean processes

- Grinding processes