Products

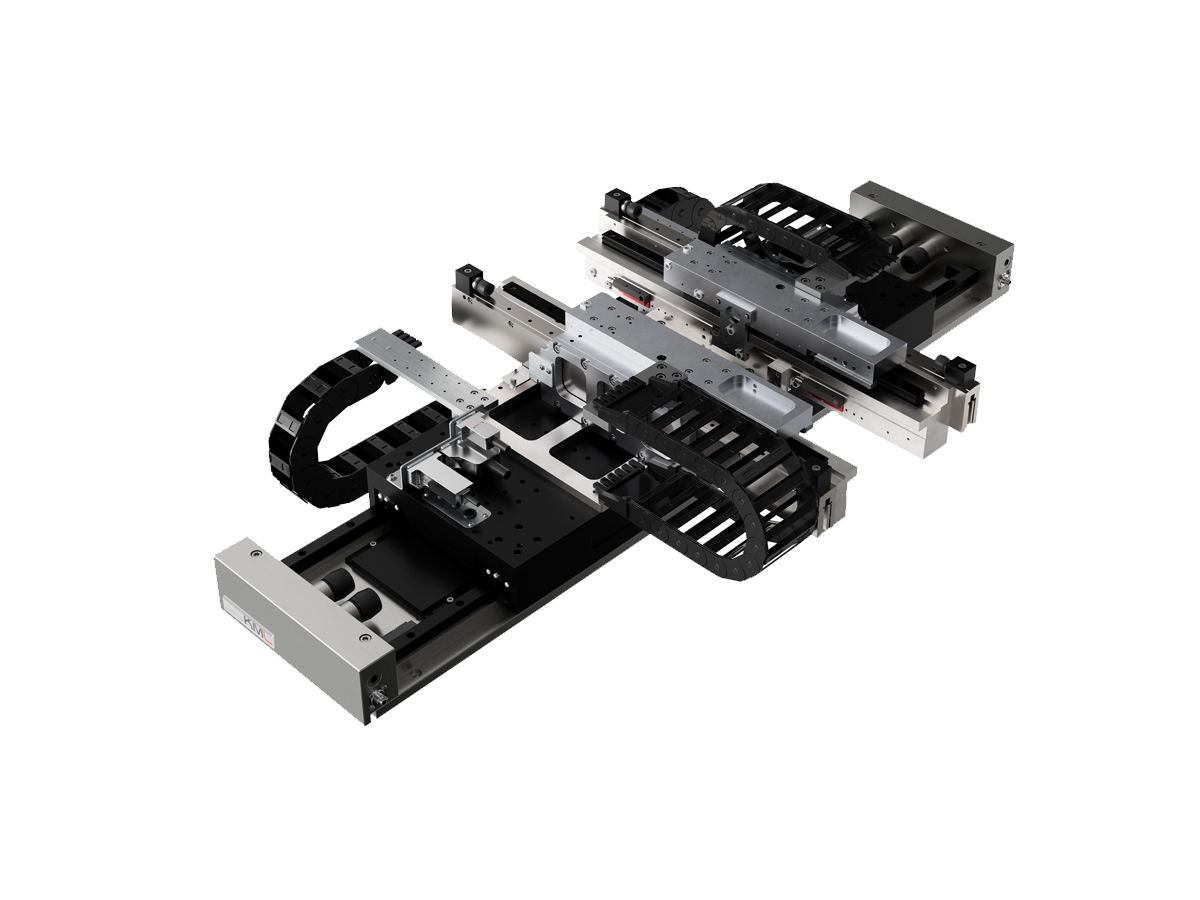

- Rigid and compact design

- Optimised process accuracies

- Integrated cable management

- Customised servo technology

The linear system, specially developed to meet customer requirements, combines precision and process stability. A high-precision ball screw drive in combination with highly rigid recirculating roller guides was used to realise the demanding running accuracies of the optical testing equipment. In addition to the integrated cable management, customer tubing and pipework were also implemented. This ensured the desired vacuum feed-through. To deliver simple plug & play, everything was assembled for the customised servo technology.

In addition to the usual customer requirements such as moving mass, the shortest possible travel ranges, cycle definitions, etc., it was necessary to take additional properties into account. These included for example:

- Lengthy maintenance intervals

- Customer-specific burn-in tests

- Electrostatic discharge capability (ESD)

- Preparation of central lubrication system

- Optical test equipment

- AOI handling

- Optical wafer test systems

- Camera adjustments

- Laser processing

- Sensor positioning