KML Precision Machining GmbH

KML Precision Machining GmbH is a fully independent subsidiary of KML Linear Motion Technology GmbH and specialises in precision machining.

Extremely broad and in-depth expertise, perfectly calibrated and state-of-the-art machinery, validated processes, and a specialised workforce form the foundations for our consistently high manufacturing quality.

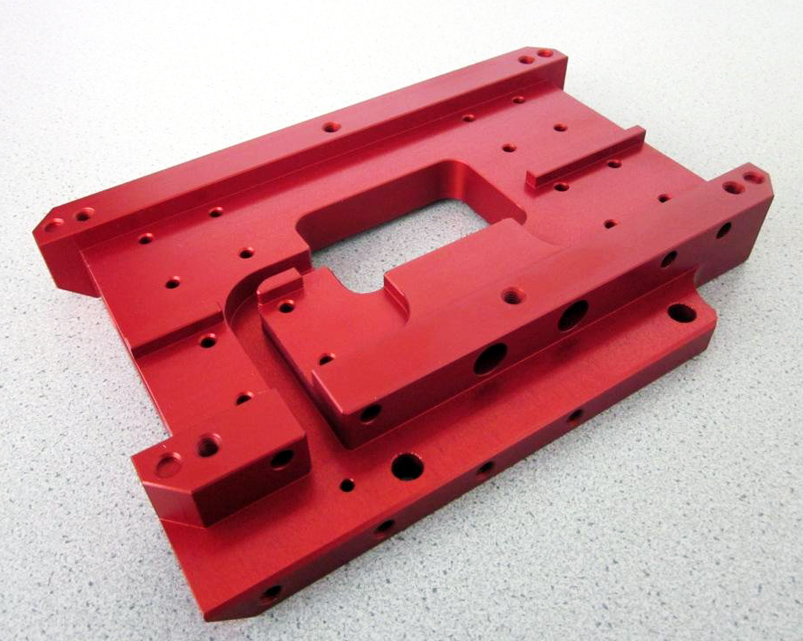

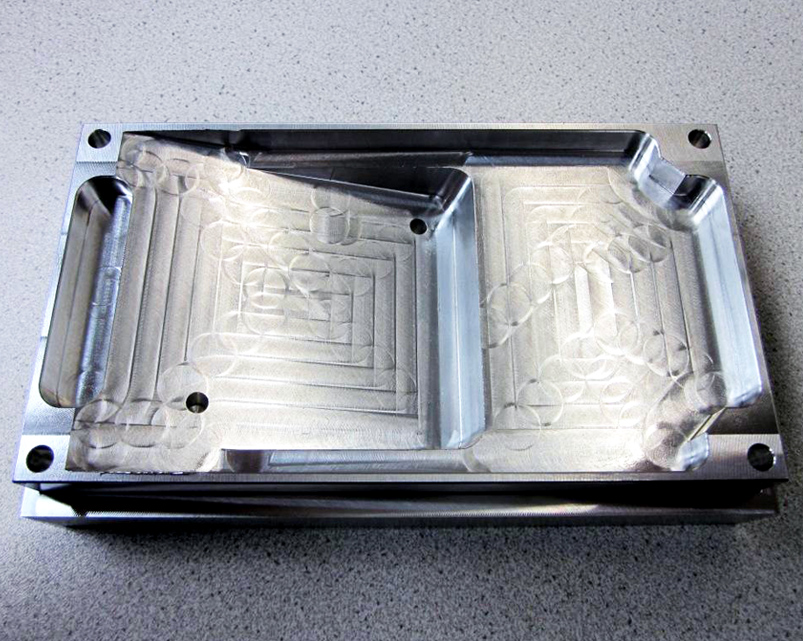

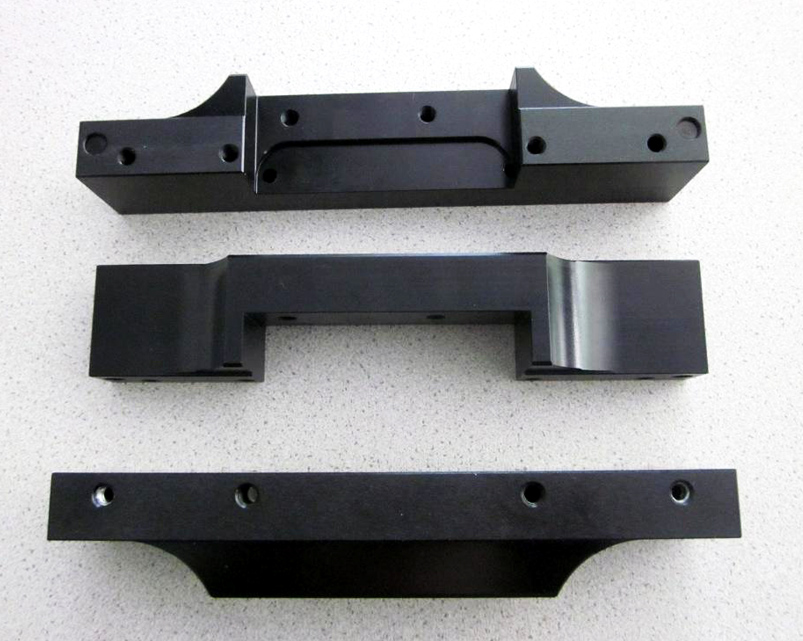

This makes us the right partner for the machining of series parts and components to be individually manufactured in the highest quality and with optimised throughput times. By applying modern CAM programming, we are sustainably able to implement even complex geometries and free-form surfaces for you.

We also use turning-milling centres, horizontal machining centres and various CNC turning and milling machines with a wide range of machining spaces.

In addition to processing aluminium, steel, various plastics (PVDF, PTFE, etc.) and titanium, we also machine various stainless steels and cast materials in 2-3 shifts/day. Production includes individual parts as well as assemblies and high-precision, complex manufacturing parts. As a rule, the components are produced in medium to large series.

Turning

Ø 5 – 670 mm

Max. length 1500 mm

Rods up to Ø 80 mm

Milling

2000 x 800 x 720 mm

Grinding

Cylindrical grinding:

350 x 1000 mm

Surface grinding:

500 x 1000 x 350 mm

Measuring

900 x 1800 x 650 mm

Our machinery

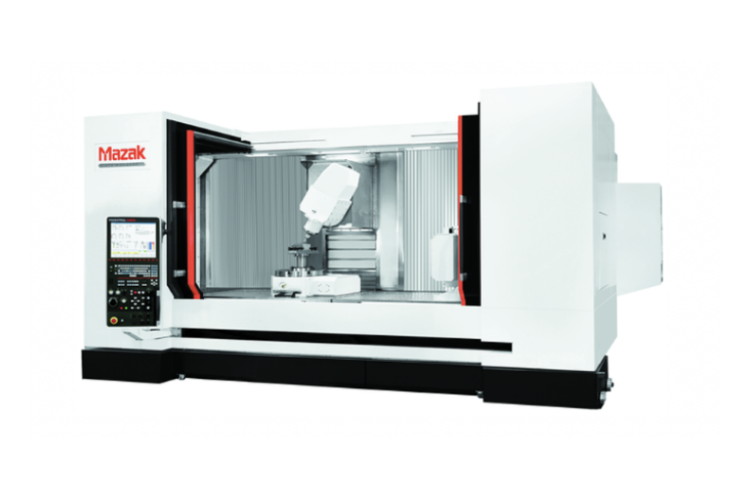

2x interlinked MAZAK HCN 5000 Horizontal 4-axis milling machine

X= 730 mm / Y= 730 mm / Z= 730 mm

12 pallets 500 x 500 mm

Workpieces up to Ø 800 x 1000 mm, 700 kg

Spindles: 18.000 rpm è 35 kW / 168 Nm

B-axis NC

70 bar IKZ

160 tools respectively

MAZAK VTC-800 20SR Vertical 4/5-axis milling machine

X= 2000 mm / Y= 800 mm / Z= 720 mm

Workpieces up to 1700 kg

Spindles: 18.000 rpm è 35 kW / 168 Nm

70 bar IKZ

5th axis as A-axis/C-axis

48 tools

HERMLE C40 Vertical 5-axis milling machine

X= 840 mm / Y= 700 mm / Z= 500 mm

Workpieces up to 500 kg

Spindles: 18.000 rpm è 15 kW / 130 Nm

80 bar IKZ

82 tools

MAZAK Integrex i-300 U1500 5-axis turning and milling machine

Turning: up to Ø 658 mm / L=1500 mm

Workpieces up to 1000 kg

Spindles: 4000 rpm

30 kW / 724 Nm

Milling spindle 12.000 rpm

22 kW / 120 Nm

Tailstock

70 bar IKZ

110 tools

CMZ TD Y Z1350 Turning machine with driven tools

Turning: up to Ø 550 mm / L=1350 mm

Workpieces up to 1000 kg

Spindles: 3000 rpm

48 kW / 1.500 Nm

Revolver: 12.000 rpm

13 kW / 105 Nm

Tailstock

15 bar IKZ

12 tools

STUDER S31 Cylindrical grinding machine

Centre distance 650 mm

Centre height 175 mm

Components up to 80 kg

2 outer discs / 7.5 kW

1 inner disc / 7.5 kW

B-axis NC

Tailstock, steady rest

Okamoto ACC-105DX Surface grinding machine

Grinding area 1000 x 550 mm

Components up to 600 kg

Reference parts